s.i.g. Sigra Imprim Group

Airmed

Supply system with compressor for medical air

Medical Air: what is it for?

Medical air is a medication commonly used within hospitals and healthcare facilities for various purposes:

- For aerosol therapy and ventilatory therapy

- For anesthesia

- As an alternative to oxygen

- As a pneumatic fluid for surgical instruments (for drilling, sawing, dissecting, and screwing)

- For drying and testing medical devices

Medical air requires purified and clean compressed air and must be 100% reliable. For this reason, it is always better to produce medical air on-site in order to reduce operating costs, avoid the use of cryogenic oxygen and nitrogen tanks, and have full control thanks to the on-site hospital pharmacy.

AIRMED: class IIb technology for high-quality medical air

Our AIRMED is the first medical air compressor supply system to be certified class IIb according to the new Regulation 2017/745/EU (MDR)

It is PED certified according to the European Union Directive 2014/68/EU and complies with the European Pharmacopoeia, ensuring purity and precision according to rigorous standards.

AIRMED utilizes the compression and filtering process of ambient air, employing a compressor, coalescing filter, dryer, filter chain, sterile filter, and a buffer tank.

Moreover, it is equipped with a water and oil separator for condensate and waste treatment, includes a gas analysis panel with a CO2 sensor to verify air quality, and a smoke detector to prevent fire hazards.

Process management occurs automatically through an electrical panel and PLC:

- Remote communication with MODBUS protocol

- Alarm notifications via SMS (optional)

- Availability of clean contacts

- Standby mode

The available models have been designed by our engineering team according to the needs of hospitals, private clinics, and laboratories:

- Airmed 25: ideal for small facilities, provides the basis for an efficient production of medical air.

- Airmed 55 and Airmed 115: designed to meet the needs of medium and large facilities, offering enhanced capacity and functionality.

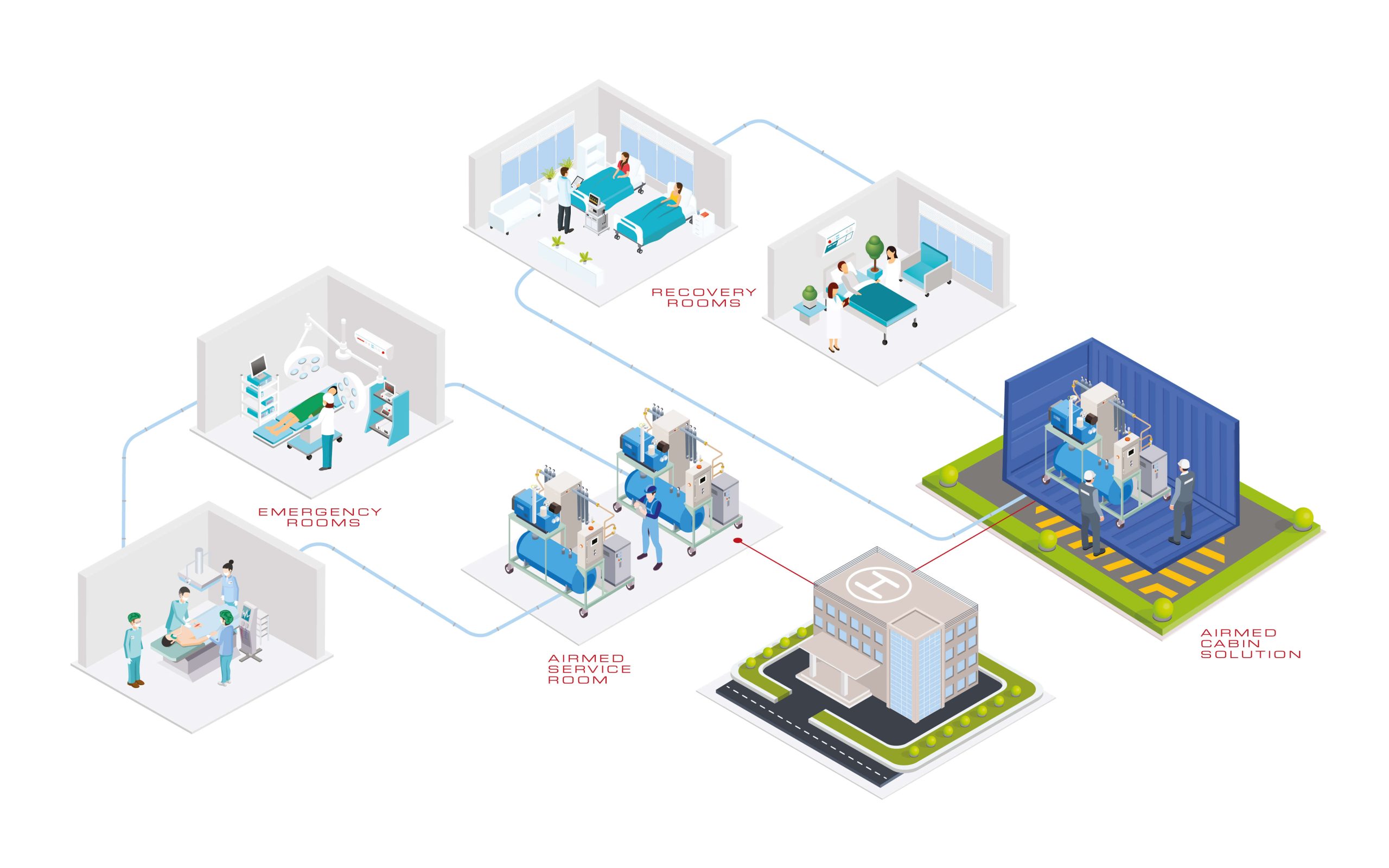

AIRMED is also available in its “CABIN” version, suitable for outdoor installations:

- Fully insulated and air-conditioned.

- Easily transportable.

Main features

AIRMED integrates precision components to ensure the highest quality of medical air:

- Compressors and Filters: Provide clean and dehumidified pressurized air.

- Dryers and Filtering Chains: Ensure further purification of air according to European Pharmacopeia standards.

- Storage Tanks: Maintain a reliable supply of medical air.

- Safety Systems: Include smoke detectors and CO sensors, with integrated alarm systems for secure management.

Commitment to durability and ease of maintenance

With a designed lifespan of 10 years and minimal maintenance requirements, AIRMED is built to last, ensuring that your facility can rely on a reliable source of medical air for years to come.