s.i.g. Sigra Imprim Group

DB1

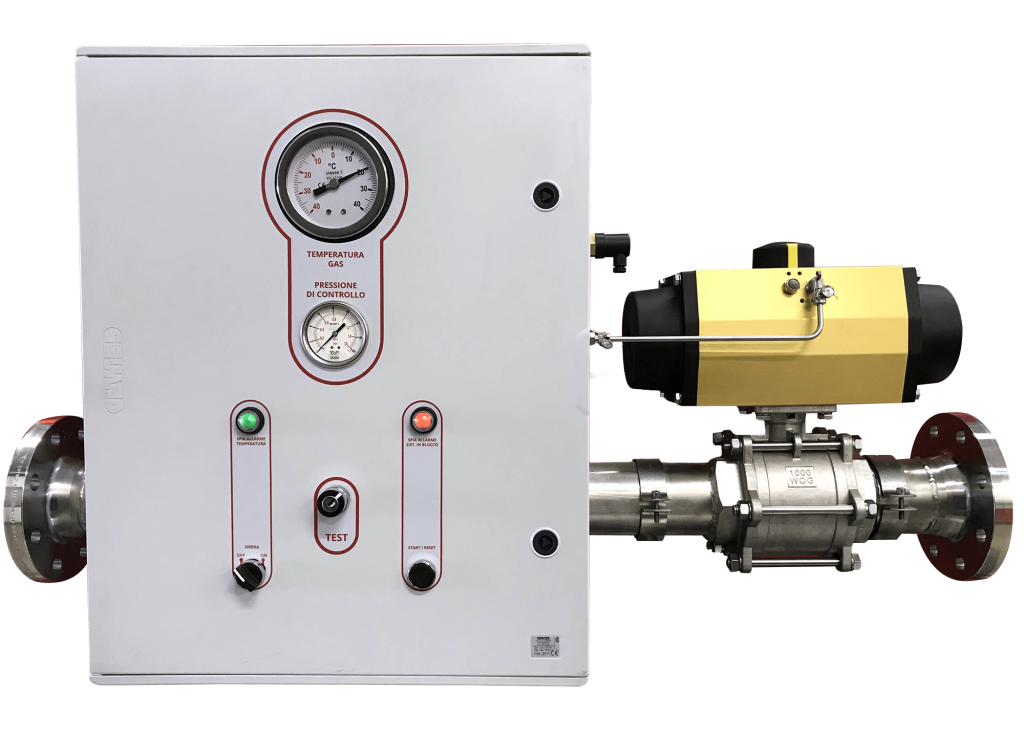

Blocking device

Safety in gas flow control

The DB1 shut-off device is an innovative solution designed entirely by S.I.G. It is used to intercept the flow downstream of a vaporizer of a cryogenic fluid when the gas temperature falls below the minimum threshold provided by the plants design as required and specified by ISPESL Circ. no. 09 dated 19/07/04.

It therefore performs a safety function aimed at preventing the risk of rupture caused by low temperature where equipment and materials downstream of the vaporization system are made of non-resilient materials.

DB1 meets the highest safety and quality standards; in fact, it complies with Regulation (EC) No. 1272/2008 and relevant directives, ensuring oxygen compatibility and adaptability to a wide range of operating temperatures.

Advanced technology for maximum reliability

Each DB1 device integrates advanced features to offer:

- Operation without any external power supply; it is self-powered by utilizing process gas.

- Continuous gas temperature monitoring for precise lockout action.

- Remote reporting for timely management of alarms and system functionality.

Main features:

- Temperature sensor

- Pneumatic logic

- Pneumatically activated blocking valve

- Pneumatic acoustic alarm / visual indicator

- Gases: N2 / Ar / CO2 / O2

- Design pressure 40 bar

- Design temperature Tmin – 25° C / TMax + 50° C

- Oxygen-compatible materials: Brass OT58, Bronze B10, PTFE, FKM, Stainless steel

Flexible configurations for every need

Available Sizes: DN25 / DN40 / DN50 / DN80

Customized Version: For some systems, where the line pressure is insufficient for opening the pneumatically actuated valve, it will be necessary to insert the bypass system called “auxiliary inlet” in order to supply the pneumatic system with an external source provided by the Customer.